What Affect the Cleaning Efficiency of Lint Cleaner

Lint cleaner is an ideal machine for cleaning the impurities contained in lint cotton. Even though with high efficiency, there are still some factors that affect its working efficiency, moisture regains, input quantity, etc.

The Importance Of Lint Cleaning

Lint cleaners improve the grade and market value of cotton. There are two types of lint cleaners used in general: airflow type lint cleaner and saw type lint cleaner. They both have their advantages in lint cleaning.

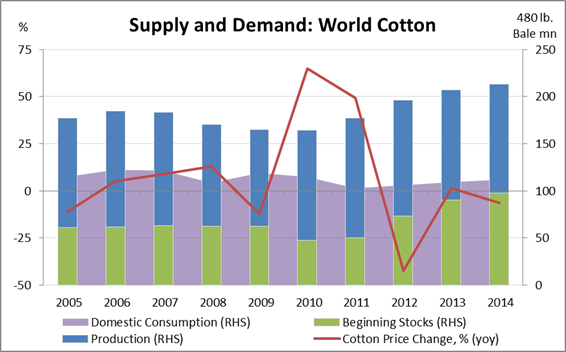

World Cotton Production and Consumption

The supply and demand of cotton will directly affect the cotton price. The production of cotton in 2014-2015 was reduced, but the world cotton consumption will increase due to the increasing mill use.

Cotton Industries In Pakistan

Pakistan is the fourth-largest producer of cotton in the world and the third-largest spinning country in Asia. Cotton production supports Pakistan’s largest industrial sector.

How to Safely Operate Lint Cleaner

Lint cleaner is mainly used in cotton processing procedures to remove impurities. Before using it efficiently, we should do some preparation work. Here are some kind tips for safe operation.

History of Cotton Harvesting Machine

Cotton is difficult to harvest for its own features, which increases the demand for cotton picking machines. Like many other great inventions, the appearance of the cotton picker experienced a long time.

China Made Cotton Picker

China-made cotton picker had been used for cotton harvesting for years, it is popular among customers due to its good performance, good quality and cheaper cost.

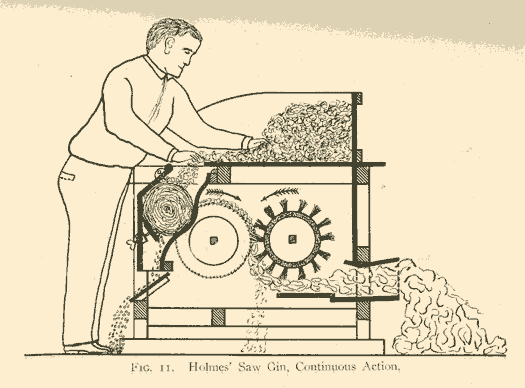

The History of Cotton Gin Machine

Cotton Gin Machine Brief Introduction. Devices for separating the cotton fiber from seed have existed since 4000 BC. All the currently available ginning machinery in the world is based on two fundamental principles: roller ginning and saw ginning.

How to Delint the Cottonseed

Cottonseed, as the by-product of cotton ginning operation, is covered with fibrous lint. Two general methods have been developed for removing the lint from cottonseed, which are removing the lint by acid and by delinter machine respectively.

General Introduction of Cotton

Cotton has wide application in our social life. Even every part has its unique usage. It can be classified into three types, long-staple cotton, medium staple cotton, and short-staple cotton.