Cottonseed, as the by-product of cotton ginning operation, is covered with fibrous lint. The cottonseed is mainly made up of an inner kernel, usually called “meats”. This meaty portion contains all the oil as well as proteins, and it is enclosed in the fibrous hull. Over the hull stick out the cotton fiber which escapes the ginning and left on seeds. These cotton fibers are called “lint”.

By processing cotton seeds, we can get maximum benefits. The inner kernel can be planted, fed to livestock, made into cottonseed oil for human consumption, used for fertilizer, or used in products like lotions and soap. The lint we get from cotton delinting has wide application in the cotton blankets, sweatshirts, paper board industry and cotton pulp, etc. Therefore, the cottonseed delinter is very essential in cotton processing.

Methods of Cottonseed Delinting

Two general methods have been developed for removing the lint from cottonseed, which is removing the lint by acid and by delinter machine respectively.

The acid delinting of cottonseed has been used extensively, particularly when the seeds are used for planting. Both sulfuric acid and hydrochloric acid have been used for acid delinting respectively. Due to the generation of heat from the reaction of the acid with the moisture, the short cotton fibers on the seed would quickly disintegrate. The residue can be washed away with water. After washing, the seed needs to be neutralized with soda ash, lime, or anhydrous ammonia, which is regarded as the wet acid method. However, the concentrated sulfuric acid is extremely corrosive to machinery and dangerous to handle. Some serious problems could emerge, like consuming a large amount of energy to dry the seed and causing soil and water pollution.

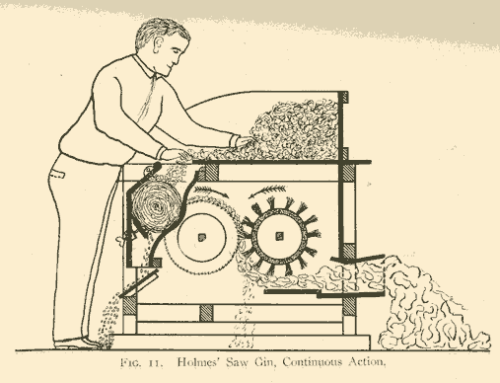

Mechanical delinting requires more energy than acid delinting, but it does not use any chemicals and can produce a small quantity of usable low-grade lint as a by-product. Mechanical delinting is usually accomplished by high-speed rotating sharp saws or abrasive surfaces to cut or rub the fibers off from the hull. The advantage of this type of operation is that the fibers are not degraded during the operation and can be sold for various purposes. Also, since the seeds are to be subsequently crushed for oil or meal, the damage sustained by the seeds is not detrimental to their further use. The delinter machine also provides for the recovery of the lint after separation from the cottonseed. The movement and travel path of the cottonseeds during the delinting process is controlled to ensure a high degree of efficiency in the removal of the lint.