Why We Use Lint Cleaner

Lint cleaner can remove trashes, such as leaf particles, motes, grass and bark that remains in cotton, which will improve the grade and market value of cotton. However, excessive cleaning can reduce bale values and some quality factors.

In addition to removing trash, lint cleaners comb and blend the cotton to produce a smooth appearance. But they may degrade some desirable mill qualities, especially at low moisture. The process of lint cleaning also has an important effect on fiber quality. Under-cleaning may lead to excessive trash and bring potential price losses to cotton growers, but excessive cleaning may reduce the quality of the cotton fiber, such as more short fibers.

Types Of Lint Cleaner

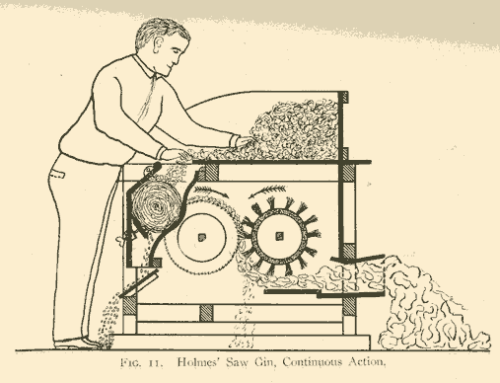

There are two types of lint cleaners in general: airflow type lint cleaner and saw type lint cleaner. Airflow-type lint cleaners are commercially known as the Air Jet/Super Jet, Centrifugal Cleaner, or Super Mote Lint Cleaner. It doesn’t has saws, brushes, or moving parts and is usually installed immediately behind the saw or roller gin stand. When air and cotton move through the duct, they change indirection abruptly as they pass across a narrow trash-ejection slot. Foreign matter that is heavier than the cotton fibers and not too tightly held by fibers is ejected through the slot by inertial force. Compared with saw lint cleaners, airflow-type lint cleaners are less effective in improving the grade of cotton because air lint cleaners do not comb the fibers. However, air lint cleaners do remove less weight from the bale and do not affect fiber length, fiber strength, and neps.

What Should Note During Lint Cleaning

What Should Note During Lint Cleaning

The lint cleaning process is important for improving the grade and market value of cotton. Lint-fed rates should be suitable. High rates of lint fed to the cleaning machinery will decrease the cleaning efficiency and perhaps lower bale values. The best feed rate is about 750 kg/hr/m (500 lb/hr/ft) of saw-cylinder length, which will do minimum damage to the cotton and increase the cleaning efficiency.

It would likely be useful to combine the saw-type lint cleaner with airflow type lint cleaner. However, it must ensure that the air-type lint cleaner removes most of the motes and large trash particles before the cotton reaches the saw-type cleaner. This could prevent seed-coat fragments from breaking into smaller ones, which is more difficult to remove during saw-type lint cleaning.